ProteusCore | Radar processing software

Traditional maritime Radar presents a paradox: it’s essential for safety yet notoriously difficult to interpret. Since 2019, our technical team has been capturing and analyzing one of the largest marine Radar training datasets. Tocaro Blue harnesses this massive proprietary Radar dataset to train the ML models embedded in ProteusCore™, transforming ordinary off-the-shelf Radar into an AI/ML-driven Radar detection and classification solution.

2,000,000+ Frames of radar data

The ProteusCore configuration app allows for viewing of the ProteusCore ML pipeline, and configuration of Radar and NMEA 2000 settings

AutoFocus (Auto-Gain & Range)

Radar systems traditionally require frequent manual Radar gain tuning and range setting. ProteusCore offers a patent-pending Autofocus feature that optimizes object detection based on environmental conditions, sea state, and proximity to land. ProteusCore fine-tunes the precise settings of the Radar so that the machine learning model can accurately find and classify objects in the Radar field-of-view. This comprehensive object detection capability delivers crucial real-time data to vessel operators or autonomous vessel control systems.

The ProteusCore configuration application (shown) automatically adjusts range and gain

Radar based classification

After detecting targets with the Radar, ProteusCore applies Tocaro Blue’s proprietary machine learning models to decipher the contents of the Radar images. Using sophisticated data filtering and machine learning, ProteusCore is able to analyze Radar images and determine the class of detected objects. This unique capability offers more context and information than ever before from Radar. Now your Radar knows whether a detection is a small or large vessel, a marker or buoy, and even land or wake. This is critical to informing your navigation for your autopilot system.

Advanced tracking

ProteusCore tracks hundreds of objects, automatically acquiring, tracking and discarding trackers as objects move in and out of view. Our system provides highly precise outputs without requiring any manual intervention.

For each tracked object, ProteusCore reports position, closest point of approach, velocity, and predicted trajectory.

The ProteusCore software maintains a list of targets for all objects around the vessel, in real-time

Radar-based Advanced Driver assistance systems

With a 360-degree field of view, Radar is a compelling sensor for advanced driver assistance systems (ADAS) development. With the output of ProteusCore, developers can ingest Radar–classified tracks for collision detection and avoidance. Smart Autopilot systems can leverage ProteusCore to make throttle and steering adjustments to avoid tracked targets in the vessel’s path.

Radar can be used as a perception sensor to inform autopilot systems about potential collisions. ProteusCore functionality can be used to provide alarms and alerts to the captain

machine vision camera + radar fusion

As an addition to your camera system, ProteusCore can offer improved distance measurement and enhanced target tracking performance. ProteusCore target tracking can inform where to point the camera and provide 360-degree awareness.

Sea.AI Sentry with Radar+Camera enhanced perception technology

Deployability | Cost efficiency

ProteusCore only requires CPU processing, meaning it can be a more cost effective solution to implement than EO/IR camera or LiDAR based solutions that require expensive hardware.

In most cases, ProteusCore can run on your existing hardware and deployed using our ProteusCore App or SDK.

Tocaro Blue also offers hardware devices for ProteusCore deployments.

Industries

Our Radar perception technology is used across the marine industry. From cruisers and fishing boats, to workboats and uncrewed surface vessels, Radar perception appeals to a broad range of applications and environments.

Real-time situational awareness tools for Tactical Craft and USVs

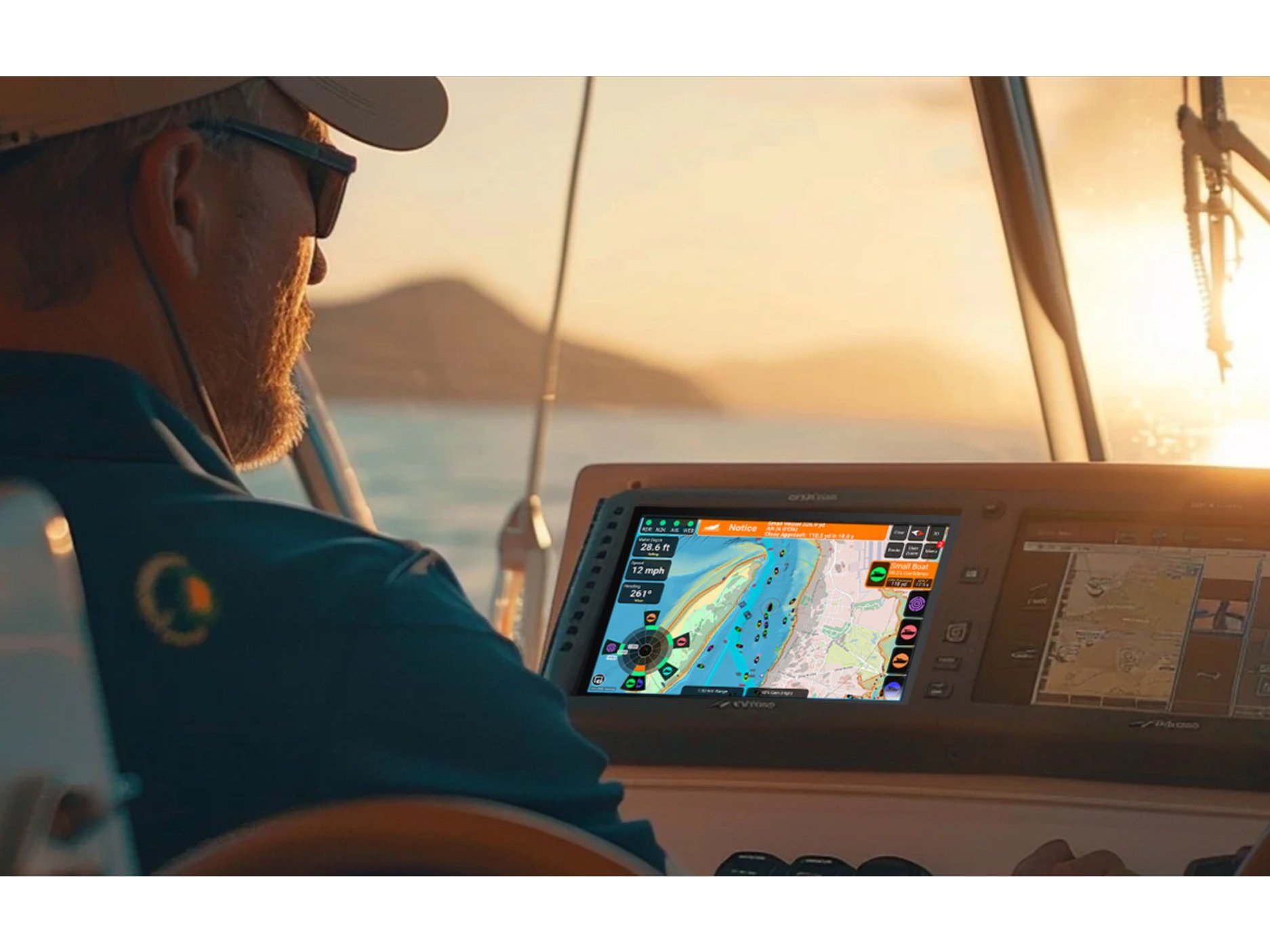

ML Radar processing for Next-Gen UI design and advanced driver assistance

Modern Marine Navigation for Recreational Boaters

Contact us.

Looking for more information about the ProteusCore solution? Fill out our contact form to Download our ProteusCore technical product summary!